Views: 0 Author: Site Editor Publish Time: 2025-11-07 Origin: Site

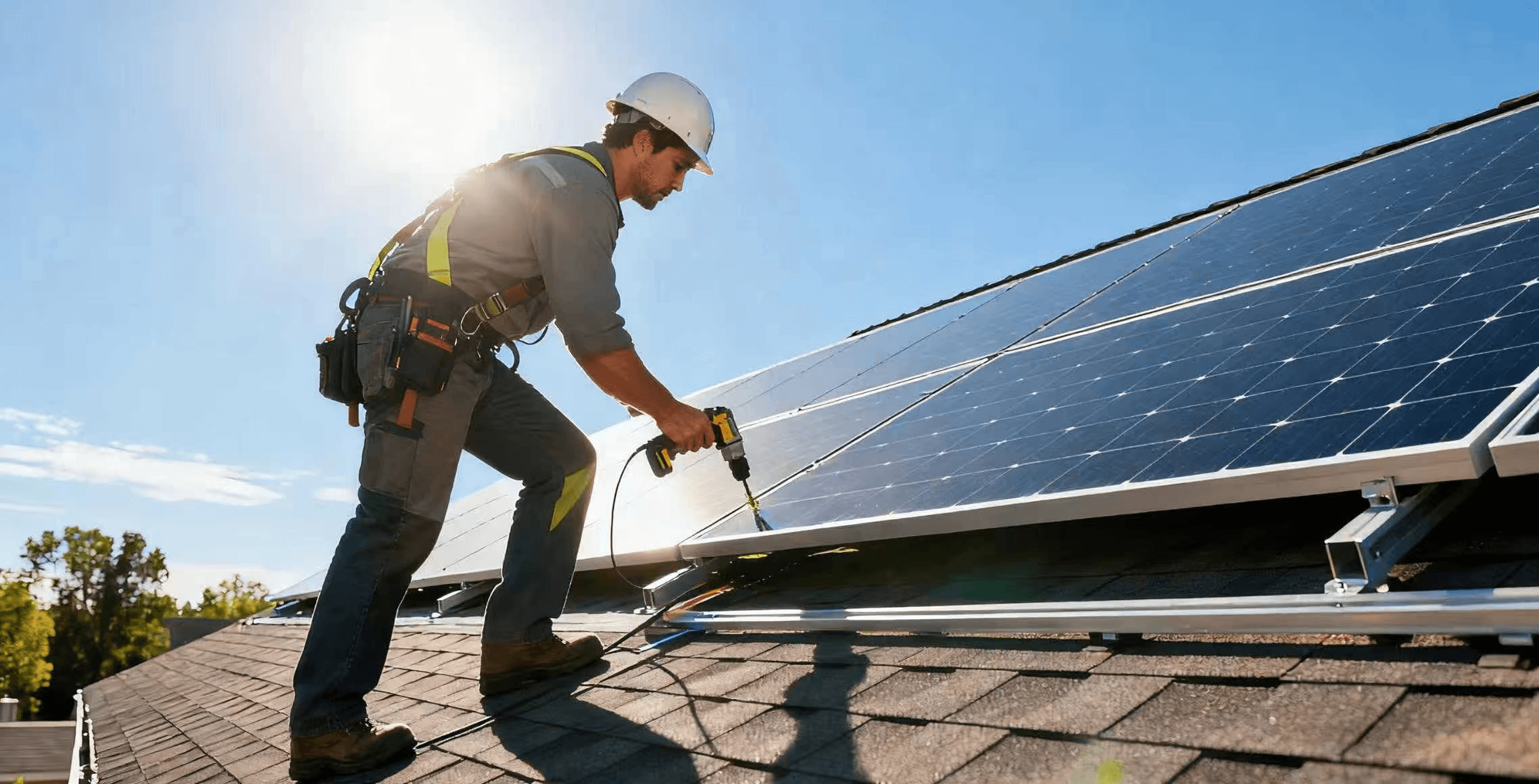

Solar panel installation isn't just about "nailing solar panel to a roof"—it directly determines how much electricity you'll generate, whether the system can last over 25 years, and if you'll end up spending tens of thousands on rework later. I've been in this industry for over a decade, and let me be honest: in 2025, solar panel power is getting higher (like those high-wattage or bifacial modules), and local regulations are stricter. Cutting corners during installation can cause annual power generation to drop by 10%-30%, and in severe cases, even ruin the entire system. Whether you're a professional installer, a distributor advising clients, or a homeowner overseeing a project, this updated guide will keep your system running stably for years.

I've seen too many projects fail because this step wasn't done right. Take the time to do these three things:

First, figure out if your site is actually suitable for solar panels and if the structure can support the system's weight:

Sunlight Check: Use PVsyst or solar mapping apps to confirm the site gets at least 4 hours of unobstructed sunlight daily. I once saw a project where the client didn't notice a tree would grow tall enough to block the solar panels in two years—total waste. Mark shadows from trees, chimneys, and neighboring houses—even a little shade can drastically reduce efficiency, especially with older string inverters.

Structural Safety: For roof installations, ensure the structure can bear at least 40kg/㎡. Flat roofs may need additional reinforcement, and for sloped roofs? First check for damaged tiles or aged waterproofing. A client skipped this step, and after a heavy rainstorm, a solar panel collapsed through the roof—messy and expensive to fix. For ground installations, test soil bearing capacity and avoid low-lying areas prone to waterlogging.

Regulations and Grid Connection: Check local regulations—some areas require permits for systems over 5kW, and others have strict requirements for wind and snow loads. Also communicate with the power supply bureau: confirm grid voltage and ensure the inverter is compatible with their equipment. I've seen many projects delayed for months because this wasn't checked in advance.

The quality of installation depends entirely on the weakest component. I always tell clients these points:

Rack Compatibility: Choose rack material based on climate—aluminum is lightweight, and stainless steel resists coastal corrosion. If you're in a typhoon-prone area, select racks with high wind resistance. We worked on a project,because the right racks were chosen, they survived a hurricane unscathed.

Inverter Size: The inverter power should match the solar panel array—too large wastes electricity, too small limits output. Prioritize MPPT (Maximum Power Point Tracking) inverters with over 98% tracking efficiency, which perform better when sunlight changes. I've seen many systems with mismatched inverters that never reached the expected power generation.

Cable Quality: For 5kW systems, use TUV-certified cables with a cross-sectional area of at least 4mm² to reduce energy consumption. If cables are exposed outdoors, choose those resistant to high temperatures and harsh weather. Buy cheap low-quality cables? They'll definitely damage within a year.

Safety regulations are stricter in 2025. Prepare in advance and don't cut corners:

Prepare personal protective equipment (PPE): Class 00+ insulated gloves, arc flash clothing, and full-body harnesses meeting EN361 standards for high-altitude work.

Set up a safe work area: Use scaffolding or safety platforms for roof work, and attach NFPA704 signs in electrical hazard areas. Safety first, always.

Check the weather forecast: Don't install in rainy, snowy, or high-wind conditions—moisture increases the risk of electric shock, and strong winds may damage unfixed solar panels.

Every step of installing solar panels and wiring requires care, otherwise problems will easily arise.

The rack is the "skeleton" of the installation—wobbly racks will definitely damage solar panels or reduce efficiency. Here's my approach:

First Lay the Foundation: For ground installations, use C25 concrete bases, dug below the frost line (1.2-1.5 meters deep) to prevent frost heave and displacement in winter. For roof installations, use custom accessories: chemical anchors for concrete roofs, waterproof clamps for metal roofs, and special brackets for tile roofs—never drill directly into tiles.

Angle and Orientation: Fixed racks in the Northern Hemisphere should face due south, with an angle close to the local latitude (±5°) to maximize annual sunlight. Increase the angle by 10° in winter to capture low-angle sunlight, and decrease it in summer. For bifacial solar panels, the rack should be at least 1.5 meters above the ground to allow sunlight to reflect from below. If the rack is too low, efficiency will decrease significantly.

Check After Fixing: Tighten all bolts to 35-40N·m torque and apply thread-locking glue to prevent loosening. Add wind-resistant guy wires in hurricane-prone areas.

"shake test" every time—if it moves, re-reinforce it.

Handle solar panels with care—even small scratches will reduce efficiency, and improper installation can cause hot spots (which ruin solar panels in minutes).

Transportation and Placement: Carry by the frame (don't touch the glass) to avoid cracks. Leave a 10cm gap between solar panels and the roof for ventilation, which keeps components cool and improves efficiency by about 5%. If you install solar panels too densely, and all inverters will overheat in summer.

Array Layout: Use PVsyst for 3D modeling to ensure no solar panels shade each other between 9 AM and 3 PM (peak sunlight hours). Leave 0.8-meter-wide channels between arrays for future cleaning and maintenance. A client skipped this step, and now half the solar panels are inaccessible for cleaning.

Secure Fixing: Use stainless steel clamps (plastic ones degrade in UV light) to fix solar panels to the rack. Double-check the torque—too tight will crack the frame, too loose will allow solar panels to shift.

Wiring errors are the number one cause of system fires or shutdowns.

Cable Routing: DC cables (from solar panels to inverter) should be run through protective conduits to prevent rodent damage or exposure to wind and rain. Keep DC and AC cables at least 30cm apart to avoid interference. Leave 10%-15% cable slack to accommodate thermal expansion and contraction. If you don’t leave slack, and a cable snapped—costing a lot to repair.

Wiring Tips: Strip wires neatly (no frayed ends) and use crimp terminals with heat-shrink tubing for waterproofing. Tighten terminals firmly—loose ones generate heat and waste electricity. For systems above 120V, attach warning labels near junction boxes. Do a "pull test" after wiring—if it comes loose, rewire it.

Inverter Installation: Install in a cool, well-ventilated place (indoor or covered outdoor) with a temperature not exceeding 45℃. Keep it within 30 meters of the solar panel array to reduce line loss. If you install an inverter in direct sunlight, and it will fail near six months.

Don't consider the job finished until you've completed these checks—I've seen too many "installed" projects have problems later:

Electrical Testing: Use a multimeter to measure the DC voltage of solar panel strings—the reading should match the design value. Then test the AC output of the inverter to ensure it matches the grid voltage and frequency.

Performance Verification: On a sunny day, use a solar monitor to check initial power generation and compare it with PVsyst simulation results—a difference of more than 10% indicates a problem (such as shading or loose wiring). A system's power generation was consistently below standard; testing revealed a faulty solar panel, which was replaced under warranty.

Safety Testing: Test overload and short-circuit protection—simulate a fault and check if the inverter shuts down automatically. Ground resistance should be less than 10Ω to prevent electric shock.You can hire a professional electrician for this step to be safe.

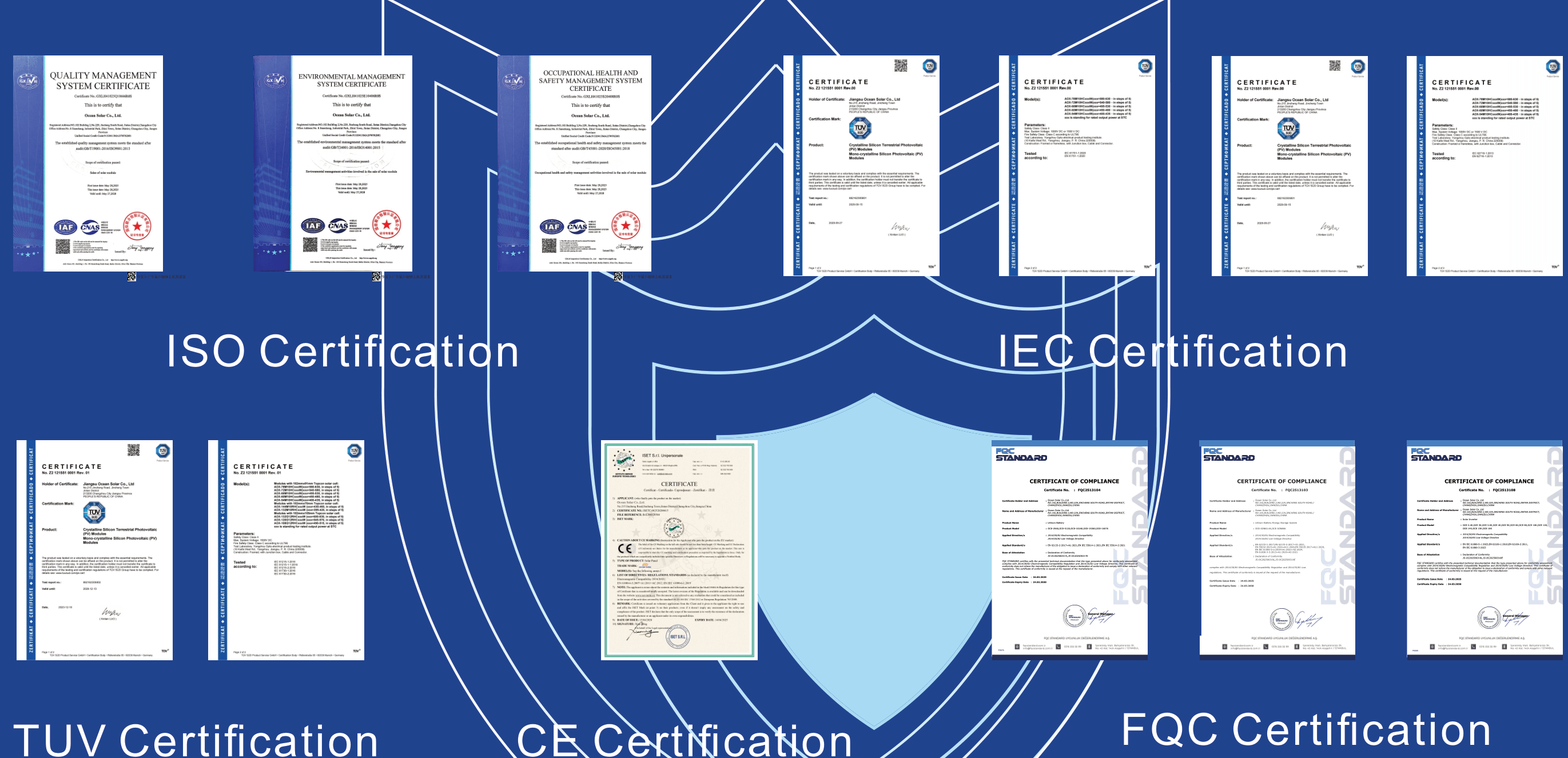

Organize all documents: permits, component warranty certificates (Ocean Solar solar panels have a 15-year product warranty and a 30-year linear output warranty), and test reports. Some clients lost their warranty documents and couldn't claim for faulty solar panels.

Explain maintenance tips to the owner: Clean solar panels every 3-6 months (more frequently in dusty areas), check rack bolts annually, and inspect wiring for damage after rain. You can create a simple checklist, otherwise most people will forget maintenance.

Install a monitoring app: Connect the system to a mobile phone so the owner can check power generation in real time and detect problems early (such as a sudden drop in power generation). A client detected an inverter fault in time this way, saving tens of thousands in repair costs.

Installation requirements vary by location—these are lessons I've learned from projects across the globe:

Coastal Areas: Use racks with anti-salt spray coating and waterproof junction boxes to resist sea breeze corrosion.

Snowy Regions: Set the solar panel angle above 30° to allow snow to slide off, and add heating strips in heavy snowfall. A client in Canada didn't adjust the angle and has to climb up to clear snow every winter.

Urban Rooftops: Use BIPV racks that integrate with the roof, and match with micro-inverters to avoid shading from surrounding buildings.

Sloped Ground: Use stepped racks to prevent soil erosion and maintain the optimal angle. A hillside project avoided landslides with this method and remains stable now.

In 2025, solar panels are an investment that can last for decades, and proper installation is the key to unlocking their value. I've seen too many projects cut corners in site assessment, component quality, and wiring to save a few days, only to spend tens of thousands on rework later—it's just not worth it.

For distributors and installers partnering with Ocean Solar, these guidelines fully match our solar panel parameters—our 450W-750W modules can seamlessly integrate with standard racks and new inverters, and our team will provide you with customized local installation checklists. Our team has worked on dozens of projects, and when installed correctly, they are extremely durable.

Want your next solar project to perform at its best? Start with site assessment, use quality accessories, and follow these steps—your clients (and their electricity bills) will thank you. If you need more opinions, feel free to contact us.

NOTE:The author has tried his best to ensure the accuracy of the above content. If you have any questions, please contact us directly for more accurate and updated industry information.

The Secret to Worry-Free Outdoor Power Lies in Portable Inverter Energy Storage All-in-One Stations

TOPCon Solar Panels: Why They’re the Hottest 2025 Solar Trend

Solar Panels vs. Solar Shingles: Which Is Better for Your Home?

How Long Do Solar Panels Last? Decoding Degradation and Key Lifespan Factors

Top 7 Solar Panel Manufacturers in Germany You Should Know in 2025

TOP solar panel manufacturers in thailand you should know in 2025

TOP 5 solar panel manufacturers in vietnam you should know in 2025